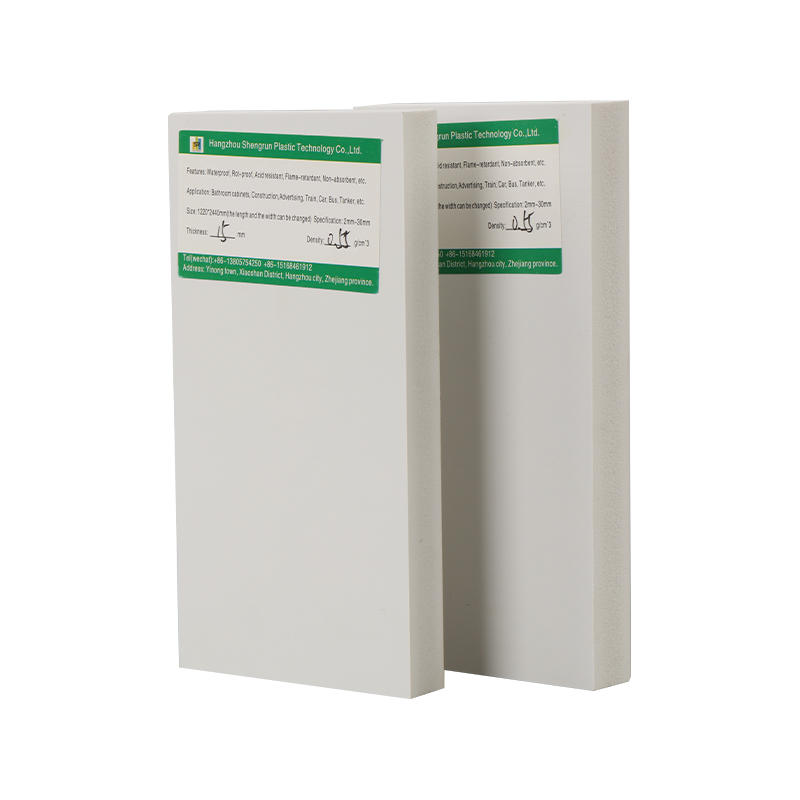

Characteristics and Applications of Low-density White PVC Foam Board

In the vast field of materials science, white PVC foam board has attracted much attention for its unique physical properties and wide application prospects. Among them, the low-density white PVC foam board, with its relatively large internal pores and sparse distribution, shows unique performance advantages and specific application scenarios.

The delicate balance between pore structure and load-bearing capacity

The reason why low-density white PVC foam board has a low density is mainly because it forms larger pores during the foaming process, and these pores are relatively sparsely distributed inside the board. This structure not only gives the board a light quality, but also brings certain mechanical challenges. When the board is subjected to external force, the connection between the pores is relatively weak, which easily becomes a stress concentration point, resulting in a relatively weak overall load-bearing capacity of the board. Therefore, when designing and using low-density foam boards, it is necessary to fully consider the limitations of their load-bearing capacity and avoid using them in environments that require high-strength support.

The dual advantages of thermal insulation and flexibility

Although low-density white PVC foam board is insufficient in load-bearing capacity, it stands out with excellent thermal insulation and good flexibility. The larger pore structure makes the board full of air, and air is a poor conductor of heat, so this board has excellent thermal insulation effect. In cold or hot seasons, it can effectively prevent the transfer of heat and keep the indoor temperature relatively stable. At the same time, the low-density foam board also has a certain degree of flexibility, which can adapt to a certain degree of deformation and is not easy to break, which provides more possibilities for it in complex and changeable application environments.

Preferred materials for specific application scenarios

Based on the above performance characteristics, low-density white PVC foam board has found its place in many fields. In the field of construction, it is widely used as insulation material, providing buildings with efficient thermal insulation effect and reducing energy consumption. In the interior of refrigerated trucks, low-density foam boards can not only maintain the low temperature environment in the car, but also effectively reduce the weight of the car body and improve transportation efficiency. In addition, in the fields of packaging, advertising production, exhibition display, etc., low-density foam boards are also favored because of their lightness, easy processing, and low cost.

Low-density white PVC foam board has shown broad application prospects in many fields with its unique pore structure and excellent thermal insulation performance and flexibility. Although its load-bearing capacity is relatively weak, it is undoubtedly an ideal material choice in scenarios where the load-bearing requirements are not high but good thermal insulation performance is required. With the advancement of technology and the continuous improvement of technology, we have reason to believe that low-density white PVC foam board will play its unique advantages in more fields and bring more convenience and comfort to people's lives and work.

English

English 中文简体

中文简体